- Home Page

- Company Profile

-

Our Products

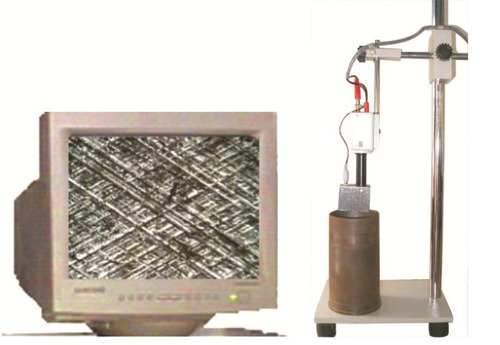

- Metallurgical Microscopes

- Microscope Accessories

- Polishing Machines

- Endoscopes and Flexoscopes

- Brake TMC Inspection SPM

- Liner Hatch Angle Measurement SPM

- Partical Size Measurement Millipore SPM

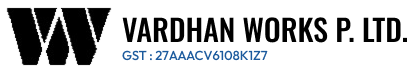

- Weld Penetration Measurement SPM

- Pipe Video Inspection SPM

- Profile Projectors

- Stereo Microscopes

- Monochromatic Light Unit & Optical Flats

- Special Purpose Microscopes

- Image Analyzer Software

- Specimen Leveler

- Hot Mounting Press

- Abrasive Cutting Machine

- Video Borescope

- Pipes Video Inspection System

- Autocollimator Telescope

- Contact Us

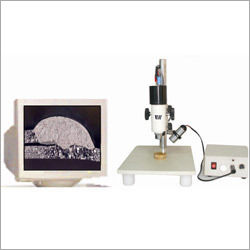

Weld Penetration Microscope

Product Details:

- Features Portable, lightweight, robust metal construction, ideal for field use.

- Focus System Dual coaxial coarse/fine focus knobs.

- View Head Monocular.

- Spare Parts Eyepiece, objective lens, illumination bulb available separately.

- Theory Used for measuring and examining weld penetration, depth, and quality in metalwork.

- Drawtube Monocular straight tube.

- Sensor High-resolution optical lens system, no electronic sensor.

- Click to view more

X

Weld Penetration Microscope Product Specifications

- Standard mechanical microscope interface. No digital connectivity.

- Fixed aperture condenser.

- Monocular straight tube.

- Not applicable (monocular).

- Not applicable (optical microscope, no digital frame rate).

- Not applicable without camera.

- Rectangular metal stage, fixed specimen holder.

- Approx. 90 mm x 180 mm x 250 mm.

- Not applicable without camera attachment.

- Adjustable LED transmitted and incident illumination.

- Monocular, straight type.

- Eyepiece, objective lens, illumination bulb available separately.

- Optical viewing only; no digital image capture.

- Approx. 50 mm from lens to specimen.

- Monocular.

- 10X widefield eyepiece included.

- Coarse and fine adjustment knobs for precision focus.

- Used for measuring and examining weld penetration, depth, and quality in metalwork.

- Achromatic objective lens 10X included.

- 20 mm coarse travel.

- Dual coaxial coarse/fine focus knobs.

- Up to 100X depending on eyepiece and objective combination.

- 2 mm fine adjustment travel.

- Integrated LED illumination, battery/adapter powered.

- High-resolution optical lens system, no electronic sensor.

- Portable, lightweight, robust metal construction, ideal for field use.

- Up to 0.002 mm (2 microns) optical resolution.

- AC adapter or rechargeable battery pack.

- Compact design with ergonomic handle for easy transport.

- Supplied with certified calibration scale (reticle) for accuracy.

- Spring-loaded clamps for secure specimen placement.

- 75 mm x 50 mm working area.

- 0°C to 45°C.

- Aluminium alloy base with powder coating for durability.

- Suitable for weld seam analysis, metal microstructure examination, and quality control in fabrication plants.

- Supplied with dust-protective carrying case.

- Approx. 2.3 kg.

Weld Penetration Microscope Trade Information

- All India

Product Description

In order to meet the needs of varied customers, we are able to bring forth Microscope with camera attachment. Designed and developed by the experts using advanced technologies. The offered microscopes are widely known to form sharp images with absolute accuracy.Engineered for Precision and Durability

Crafted with an aluminium alloy base and powder coating, this microscope combines strength and longevity, making it ideal for rigorous professional environments. The calibration scale ensures measurement accuracy, vital for weld quality assurance and microstructure studies.

Designed for Portability and Practicality

Weighing just 2.3 kg and featuring a compact, ergonomic design, the microscope can be easily carried between fabrication sites and laboratories. The included dust-protective carrying case safeguards the instrument during transport and storage, supporting uninterrupted quality control workflows.

Optimal Optical Performance

The high-resolution optical lens system, with a 10X widefield eyepiece and 10X achromatic objective, offers clear visualization up to 100X magnification. Both coarse and fine focus adjustments allow precise inspection of weld penetration and metal features, simplifying defect analysis.

FAQs of Weld Penetration Microscope:

Q: How is the weld penetration microscope used for analyzing weld seams?

A: This microscope is placed on or near the weld seam, and the specimen is secured with spring-loaded clamps. Using the integrated LED illumination and dual coaxial focus knobs, the user can achieve precise focus and magnification to assess weld depth, penetration quality, and detect any flaws in the metal structure.Q: What are the benefits of the aluminium alloy construction with powder coating?

A: The aluminium alloy base provides a strong, stable foundation while remaining lightweight. Powder coating increases durability by preventing corrosion and surface damage, making the microscope suitable for harsh, industrial environments and ensuring long-term reliability.Q: When should the specimen holders spring-loaded clamps be used?

A: The spring-loaded clamps should be used whenever a specimen needs to be securely placed on the stage for examination. They prevent movement or slippage during analysis, ensuring precise measurements and accurate focus, especially when working with small or irregularly shaped samples.Q: Where can this weld penetration microscope be effectively utilized?

A: It is ideal for fabrication plants, metalworking workshops, welding research labs, and on-site quality assurance inspections. Its robust, portable design allows use both in controlled laboratory settings and in the field, directly next to manufacturing equipment.Q: What is the process for calibrating the microscope to ensure accuracy?

A: Calibration involves using the supplied certified calibration scale (reticle) under the microscope. By aligning the scale with the eyepiece, users can verify and adjust accuracy for precise dimensional measurements of weld penetration or microstructural features.Q: How does the microscope operate without digital connectivity or sensors?

A: The microscope employs a high-resolution optical lens system for direct optical viewing; images are not digitally captured but observed through the monocular eyepiece. This traditional method ensures high optical clarity and reliability without requiring electronic image processing or frame rates.Q: What are the main advantages of using this microscope for field work?

A: Its compact build, ergonomic handle, rechargeable power options, and rugged construction make it exceptionally convenient for field use. The included carrying case and spare parts availability further support continuous, adaptable usage in diverse environments.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free